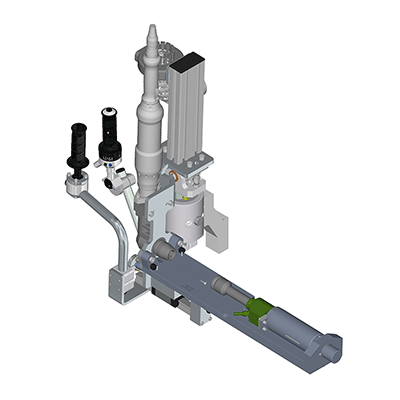

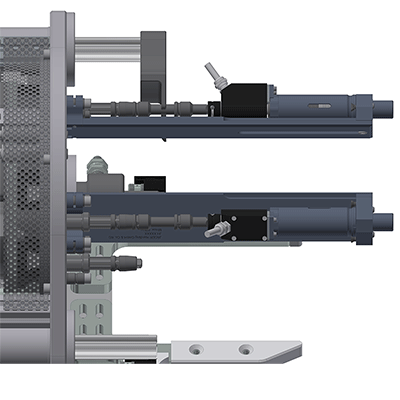

verification adapter

Adapter set for customized verification measuring with included, quick change kit. Tightening operation adapter with axial compensation and flexible cup spring packet for simulation of different tightening characters.

Suitable for verification sensor manufacturer Schatz, includes 2 pc. of extension. Not part of the scope of delivery verification sensor.

Adapter set for customized verification measuring with included quick change kit. Tightening operation adapter with axial compensation and flexible cup spring packet for simulation of different tightening characters.

Using the respective tightening operation adapter various tightening operation characters can be approximately replicated. This takes place through different layering of the included laminated cup spring. For the simulation of a hard screw joint the laminated cup spring is replaced by tempered spacers. The tightening operation adapter can be adjusted to the respectively required drive length axially via a slot in the spacing strip . Furthermore extensions in various lengths are included. The quick clamping system contained in the base plate enables an inline installation with minimum spindle distance on the lines of the Bosch BG3 drives sides. For the mounting of the adapter in front of the drive side, appropriate washers and a standard spanner for internal hexagonal bolts are required.

By means of a holding disc, which is mounted on the Schatz measuring sensor, this can be fixed against turning, so that rotation angle measurements are possible.

Suitable for verification sensor manufacturer Schatz, includes 2 pc. of extension. Not part of the scope of delivery verification sensor.

Adapter set for customized verification measuring with included quick change kit. Tightening operation adapter with axial compensation and flexible cup spring packet for simulation of different tightening characters.

Using the respective tightening operation adapter various tightening operation characters can be approximately replicated. This takes place through different layering of the included laminated cup spring. For the simulation of a hard screw joint the laminated cup spring is replaced by tempered spacers. The tightening operation adapter can be adjusted to the respectively required drive length axially via a slot in the spacing strip . Furthermore extensions in various lengths are included. The quick clamping system contained in the base plate enables an inline installation with minimum spindle distance on the lines of the Bosch BG3 drives sides. For the mounting of the adapter in front of the drive side, appropriate washers and a standard spanner for internal hexagonal bolts are required.

By means of a holding disc, which is mounted on the Schatz measuring sensor, this can be fixed against turning, so that rotation angle measurements are possible.

| item no. | size | minimal distance [mm] | max. torque [Nm] | input | total length [mm] | suitable sensor type | weight [kg] |

| 30332 | 3/8" | 30 | 50 | 4kt-3/8" | 350 | 5413-1260/50 S (Schatz) | 2.7 |

| 30331 | 1/2" | 45 | 200 | 4kt-1/2" | 650 | 5413-1200/200 S (Schatz) | 4.5 |

| 36751 | 3/4" | 62 | 500 | 4kt-3/4" | 610 | 5413-1200/500 S (Schatz) | 12.8 |

product advantages:

- verification measuring IN LINE, without dismounting of the nutrunner

- very compact design, therefore for multiple applications useable

- verification measuring also possible at nutrunner outputs without axial compensation

- tightening operation adapter infinitely adjustable for different output lenghts

- simulation of different tightening characters with flexible cup spring packet

- applicated for angle of tilt and torque measuring

- quick change kit to adapt the nutrunners

- by exchange the adapter flange to most different nut runner outputs adaptable

- applicated for fixured- and hand hold nutrunner

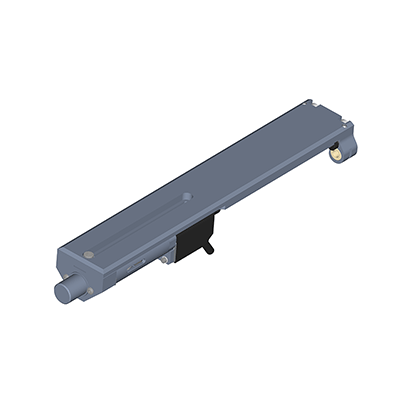

quick change kit:

push the verification adapter over the two washers and tighten the socket head screwsverification adapter axial adjustable:

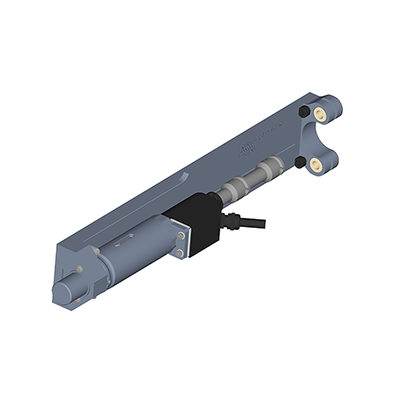

With the infinitely adjustable tightening operation adapter it is possible to mount the verification adapter on different output lengthstightening operation adapter

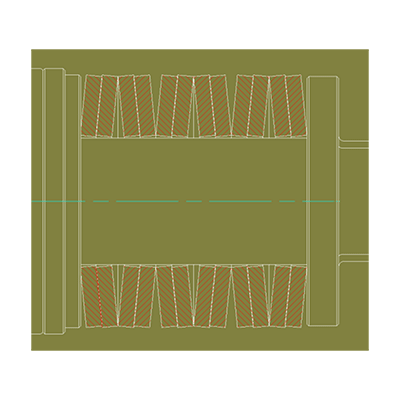

simulation of a soft tightening operation

For the simulation of a very soft tightening operations we recommend the installation of a cup spring assembly of, for example, 7 alternately layered packs with each two cup springs in the same direction.

Through this a rotation angle-controlled connection >360° using low torque rates analogue VDI 2647 is put into effect.

With same direction stacking of all cup springs (= delivery condition) and appropriately hard characteristic curve for the soft connection can be implemented. Fundamentally the following applies: An increase of the number of cup springs in same direction stacking effects an increase in the tightening operation hardness.

Through this a rotation angle-controlled connection >360° using low torque rates analogue VDI 2647 is put into effect.

With same direction stacking of all cup springs (= delivery condition) and appropriately hard characteristic curve for the soft connection can be implemented. Fundamentally the following applies: An increase of the number of cup springs in same direction stacking effects an increase in the tightening operation hardness.

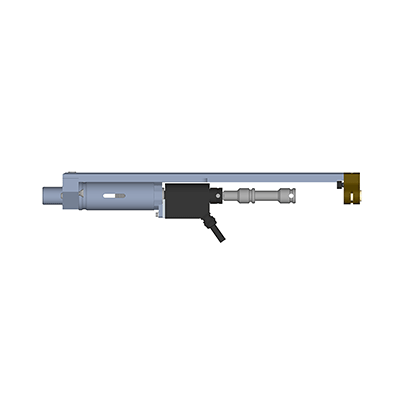

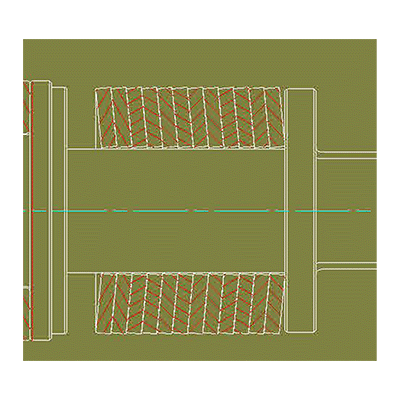

simulation of a hard tightening operation

According to ISO 5393 and VDI264 a tightening operation is hard if the final moment within a rotation angle of 0-30° is achieved, measured from 50% of the final torque.

This can be implemented in small torque ranges with the factory delivered same direction stacking of the cup springs.

In higher torque ranges the laminated cup spring can be replaced by tempered washer similar to DIN9340. Through this there results a hard to very hard tightening operation, depending on final torque and speed.

In higher torque ranges the laminated cup spring can be replaced by tempered washer similar to DIN9340. Through this there results a hard to very hard tightening operation, depending on final torque and speed.

basic information on setting of screw joint hardness

Using the laminated cup spring included in the scope of delivery and the tempered spacers there results respectively tightening operation hardness, which is fundamentally dependent on the final torque.

It is not possible to replicate the actual tightening operation hardness using this exchange part. In particular with high torques only a few discrete tightening operation hardness’s are capable of replication.

If you want the approximate replication of a tightening operation using angle-controlled final tightening (50%

tightening tests with various layering are to be carried out. Possibly further parts from the JH accessories programme are required in order to implement an adequate layering of the laminated cup spring. For this please inquire by your supplier or directly by JÄGER Handling.

It is not possible to replicate the actual tightening operation hardness using this exchange part. In particular with high torques only a few discrete tightening operation hardness’s are capable of replication.

If you want the approximate replication of a tightening operation using angle-controlled final tightening (50%

tightening tests with various layering are to be carried out. Possibly further parts from the JH accessories programme are required in order to implement an adequate layering of the laminated cup spring. For this please inquire by your supplier or directly by JÄGER Handling.

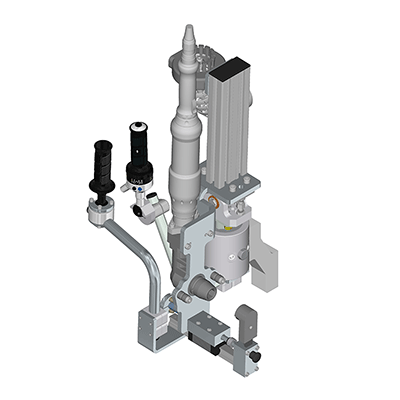

torque verification adapter on hand held nutrunner with counter holder:

verification measuring on hand held nutrunners: